- 2026

- 2024

- 2023

- 2022

- 2021

Trends in Contamination Control and the Effect on Wiper-selection

A lot discussed topic is the new draft of Annex 1 “Manufacture of Sterile Medicinal Products” of the EU GMP Guide. This shall not be another analysis of the changes but a short reflection, which effects these changes would have on the selection of cleaning materials and specifically on cleanroom wipers. The new focus of Annex1 is on Quality Risk Management (ICH Q9). Therefore, the Pharmaceutical Quality System was implemented which is focused on the following key points:

- Integration of a risk management system

- Emphasis on experts’ process know-how

- Cause analysis in the event of errors

- Separate process paths

- Sufficient exchange of information between all parties who are involved

So at the beginning always stands the risk analysis for processes, environment, and materials with the view to minimize the risk of contaminations. Here we are talking about volatile and non-volatile

residues, particles, and microorganisms. When selecting your cleaning materials you have to ensure, of course, that you remove these residues instead of bringing in new contaminants with your cleaning

products.

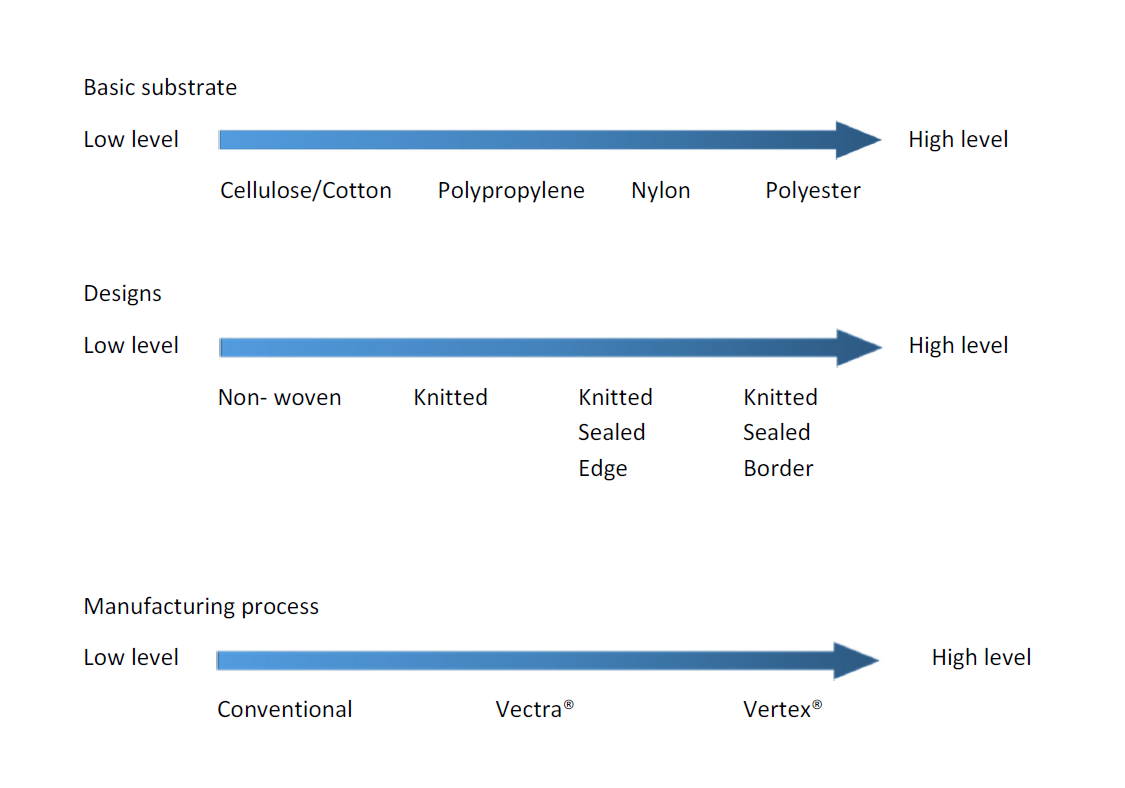

This means that to evaluate the risk, for example for cleanroom wipers, it would be necessary to learn as much as possible about substrates, designs, and manufacturing processes.

Texwipe® starts talking about conventional manufacturing with the knitted wiper material, which goes through a washing process (this is not possible with a non-woven substrate). After cutting the wiper material, the wipers will be laundered and dried in industrial washing machines. The following steps - inspection, stacking, and packaging - are manual steps under cleanroom conditions.

The Vectra® process is a semi-automatic process; gentle laundering and drying take place before the second cut (cross-cut) under cleanroom conditions is done; this will help to minimize the particle

generation of the final product. The wiper inspection is also a part of the automatic process, only stacking and packaging are still manual steps.

With the unique Vertex® process Texwipe® developed a fully automatic process in a micro cleanroom (ISO class 4-3) located in a cleanroom ISO class 8-7. Similar to the manufacturing in isolators the complete process (laundering, drying, sealing, inspecting, stacking, and packing) is executed without touching the wipers by humans. With the help of this knowledge and with the chance to discuss more your special needs with the specialists from Texwipe® it will be easier for the responsible departments to do the risk evaluation for their manufacturing process.